Hazardous substances

Hazardous substances are any kind of substance or mixture that if enters the body has the potential to cause an adverse health effect to the worker or anyone else in the work area. Hazardous substances include: solids, powers or dusts, liquids, gels, vapours, fumes, mists, gases (toxic and asphyxiant), biological agents and nanoparticles.

Substances can enter the body if inhaled, ingested, directly injected, or absorbed through contact with skin or other membranes. Single or repeated exposures over a prolonged period may potentially cause occupational asthma, occupational dermatitis, tissue or organ damage, cancer or lung diseases. Some substances can also be harmful to unborn children(teratogens) or affect reproductive function (mutagens), or can increase sensitivity to noise exposure (ototoxic).

Do you work with hazardous substances?

You might have a hazardous substance problem if you:

-

Work in a laboratory (chemicals, biologicals) or workshop (wood, metal, ceramics, paint etc)

-

Handle animals or their feed or bedding materials

-

Work with plant protective products (herbicides, pesticides, insecticides, fungicides)

-

Work with soil, plaster or cement (asbestos should not be handled)

-

Work with oils, lubricants, solvents, paints, resins

-

Undertake welding, grinding or soldering/brassing activities

-

Use specialised gases in your work

What to do next?

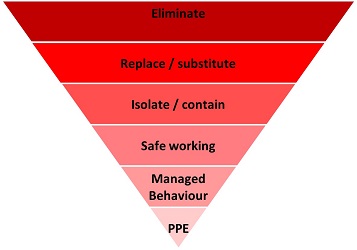

Raise hazardous substance concerns with your manager or supervisor. A COSHH assessment should have been completed as a separate or combined part of the risk assessment. The assessment should review the work and the safety data sheet, so to establish the hazard properties and routes of entry into the body and therefore what controls are needed.

There are published maximum exposure levels for many but not all substances, but in all cases, the control measures should reduce exposure to be as low as reasonably practicable.

-

Eliminate the hazardous substance, and if not possible then,

-

Replace with a less harmful substance, or

-

Substitute with a less harmful form (e.g. switch powers to pellets, use pre-mixes)

-

Isolate the worker by engineering controls (fume cupboard, or enclosure)

-

Use extraction equipment, or respiratory protection equipment (RPE) if mobile working , and use ventilation sources or work outside

-

Reduce to a minimum the quantities use, the duration and frequency of work

-

Control by safe handling procedures, including training and instruction

-

Wear personal protective equipment (PPE)

-

Health surveillance (see below)

What else to do?

Do you need help with COSHH assessing? The H&S Service COSHH e-learning course covers hazard pictograms, understanding SDS, and the COSHH assessment stages. You can also speak with your local H&S co-ordinator for guidance, and the H&S Service team is available to assist.

H&S Service can also assist with face-fit-testing of ½ masks, via safety@reading.ac.uk, and give advice on PPE.

Health surveillance

Health surveillance may be required if exposure is still likely after the control measures are applied and the substance has a known or suspected adverse health effect (e.g. dermatitis, cancer, asthmas), or if there is a specific requirement for the Health surveillance (CoP-28 COSHH). Managers and supervisors can arrange the health surveillance by completing a surveillance enrolment form.

Sources of information

-

Biological and GM risk assessment form and resources via the Biological safety pages

-

Occupational Health for referral and surveillance enrolment

-

HSE COSHH advice including safety data sheets and exposure limits (EH40) and COSHH by sector (e.g. agriculture, cleaning, welding, woodworking)

-

Machinists and metalworking fluid - Work Right to keep Britain safe

Health & Safety Services

- safety@reading.ac.uk

- 0118 378 8888

-

-

University of Reading

Health and Safety Services

Whiteknights House (W027)

Room G23

Shinfield Road

Whiteknights

Reading

RG6 6UR